CLIMATE TECH SOLUTIONS

What is CCU ?

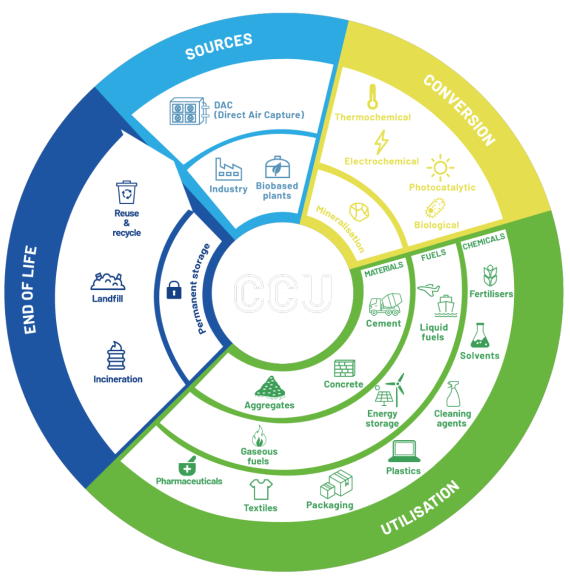

Carbon Capture and Utilisation (CCU) is a diverse set of technologies that allow for the capture and use of carbon as a feedstock for making essential products such as fuels, chemicals and building materials that today are predominantly derived from fossil resources. Such technologies are at different stages of development and some are already commercially available.

CCU technologies provide a wide range of climate-mitigating solutions to carbon-intensive sectors where no or very few alternatives exist to reduce emissions, e.g. process industry, aviation, maritime and construction. However, these technologies should not substitute large-scale efforts to prevent greenhouse gas emissions and develop more sober solutions, but complement them wisely considering the timescale of the impact, their mitigation potential based on life-cycle analysis and the most efficient use of energy and resources.

Climate

From industrial (e.g. cement plants) or energy (e.g. biomass power plants) sources: in this case, various technologies (membrane technologies, solvent absorption, adsorption, etc.) are able to separate carbon from the rest of the flue gases and isolate it.

Directly from the air, in which case we use the term “Direct Air Capture (DAC)”: ambient air is drawn through a gas trapping system where CO2 is isolated from the rest of the air and then released to be used or stored;

Utilization

Once carbon has been captured, it is then converted into essential products. There are three main categories of CCU products:

Fuels

To reach climate targets, fossil fuel-based energy demand should be mainly replaced by renewable electricity. However, there are sectors such as aviation, shipping, heavy transportation, and energy-intensive industries where hydrocarbons cannot easily be replaced by electricity, or physically not at all.

In these sectors, CCU fuels are drop-in solutions to reduce emissions and move away from fossil resources. They are produced when captured carbon reacts with hydrogen coming from water electrolysis using renewable or low-carbon electricity. CCU fuels can be stored, transported and used as such or to produce electricity again. They are easier (and relatively inexpensive) to store and transport compared to electricity and can be used in most cases in existing infrastructures. Moreover, they can be stored at large-scale over extended periods, bringing renewable energy to sectors that cannot use it directly (power-to-x). Technologies for the production of CCU fuels already exist. The first flight powered with CCU kerosene crossed Europe in 2021.

Chemicals

Most of the chemical products used in our modern daily life, such as plastics, packaging, furniture, clothing, pharmaceuticals or food and feed, are based on carbon as a key feedstock. However, the production of these products involves massive use of fossil carbon and significant greenhouse gas emissions amongst which about 60 to 70% are end-of-life emissions. CCU technologies allow bringing renewable energy to the chemical sectors and to use captured carbon as a substitute for fossil carbon, creating a circular carbon economy.

Technologies are already available to switch to CO2 and water as feedstock, but scale-up requires massive amounts of renewable energy and, for the chemical sector, the climate change mitigation potential of CCU will mainly dependent on the potential for substitution of conventional products. Cleaning products, polymers, isolation materials, textiles, etc. produced with captured carbon as feedstock are already commercialised.

Materials

The construction and building sectors emit about 25% of global CO₂ emissions. To reduce emissions, CO₂ can be permanently bound in materials in the form of minerals through a process called carbonation or mineralisation. This process is naturally occurring over geological times as seen with the formation of limestone over millions of years.

CCU processes use the same principle in an accelerated manner: CO₂ is combined for example with calcium-rich materials to produce calcium-carbonate (CaCO3), which can be used as building material either directly (e.g. as aggregate or brick) or after being further processed into cement. Mineral waste fractions such as steel slags, ashes from incineration or construction and demolition waste are abundant sources of minerals that can be carbonated by captured CO₂ to produce materials in a circular way, thereby reducing the need for landfills and the extraction of new mineral resources from quarries.

Bricks, tiles, pavements, parts of buildings and isolation materials are already produced today through CO₂ mineralisation.